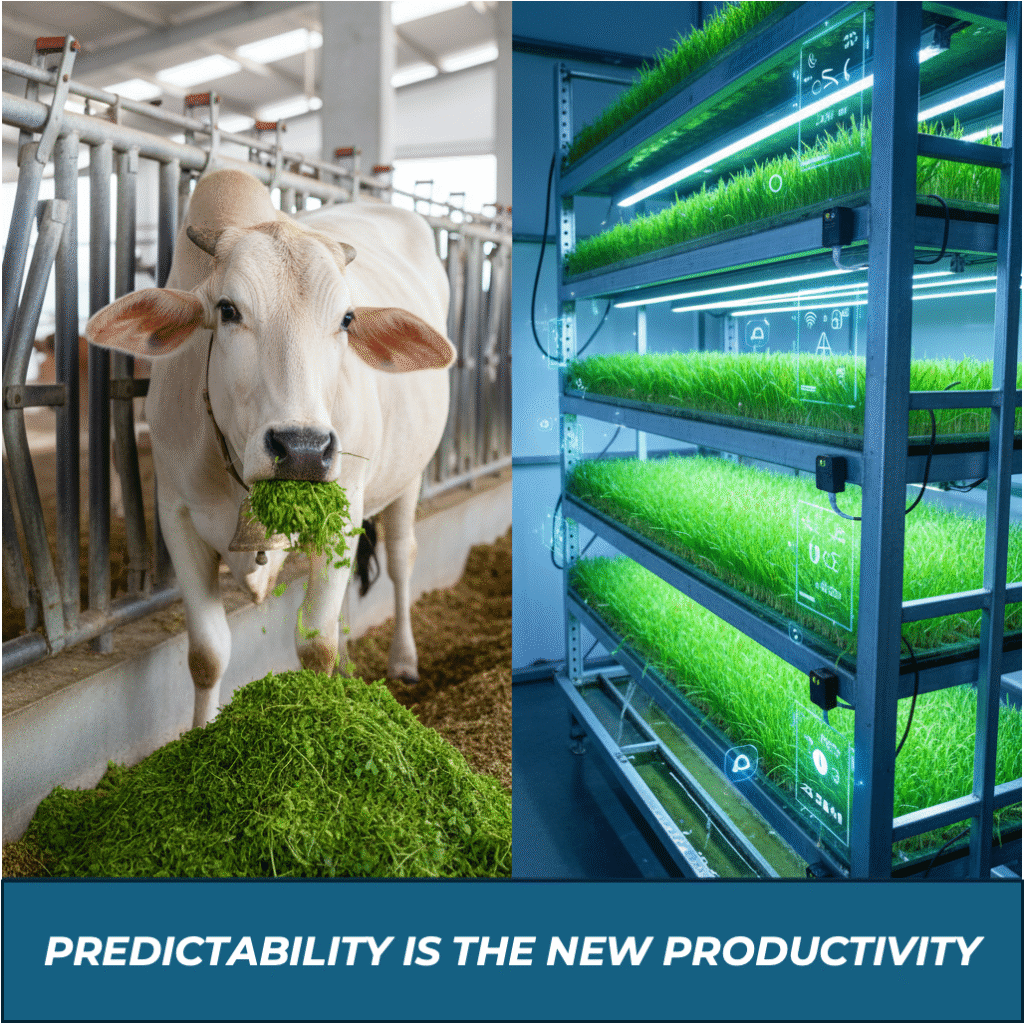

Technology in Agriculture: Building Predictable Fodder Ecosystem

When people think of agriculture, they picture soil, sunlight, and open fields. When they think of technology, they imagine sensors, data, and precision. For a long time, these two worlds seemed far apart.

But the future of Indian agriculture — especially in fodder production — lies in bringing them together.

The Challenge: Making Green Fodder Reliable

India produces more milk than any other country in the world. Yet, our 300 million dairy animals often struggle for consistent, nutritious feed. Roughly 25–30% of India’s total fodder demand goes unmet each year, especially during dry seasons.

Conventional cultivation methods depend heavily on rainfall, land availability, and local conditions. The result? An unpredictable supply of fodder — sometimes plentiful, sometimes scarce — but rarely consistent.

This unpredictability affects everything downstream: animal health, milk yield, and farmer income.

At Shunya Agritech, we’ve spent the last few years tackling this fundamental problem — how to make fodder production predictable, climate-resilient, and scalable.

The Promise of Hydroponics

Hydroponics — growing plants without soil, using nutrient-rich water — offers enormous potential for India.

- It reduces land use by 99%, allowing production even in semi-urban or arid areas.\

- It saves up to 90% of water, an essential benefit in a water-stressed country.

- It enables year-round production, independent of seasons.

Yet, early attempts at hydroponic farming in India often failed to deliver consistency. Imported systems built for cooler, less humid environments suffered from mold, infestation, and erratic yields.

To succeed here, hydroponics had to adapt to India’s unique climate — not the other way around.

Engineering the Indian Hydroponic System

The first step in making hydroponics work for India was rethinking its structure.

Most traditional systems use sprayer-based irrigation — fine mist or water sprays that keep the trays moist. But in India’s hot and humid conditions, these sprays become a breeding ground for fungus and uneven growth.

Shunya’s engineering team flipped the model. We developed the Viksit Growth System, designed ground-up for Indian climates:

- Root-Flow Irrigation: Instead of spraying, water flows gently through the root mass, ensuring uniform hydration without wetting the leaves.

- Longer, Modular Trays: Built for better coverage and drainage, these trays reduce waterlogging and contamination risk.

- Energy-Efficient Air Circulation: Simple yet effective ventilation keeps humidity in check without high-cost cooling systems.

- Smart Water Management: The system recycles and reuses water, cutting wastage by up to 95% compared to open-field cultivation.

This structural innovation alone made daily production far more stable — but structure alone wasn’t enough. To achieve true predictability, we needed data.

From Greenhouses to Smart Systems

Predictability in agriculture comes from data-driven feedback loops. Every environmental variable — temperature, humidity, pH, nutrient level — affects how a seed germinates and grows.

At Shunya, we embedded Internet of Things (IoT) sensors into our GLCs (Growth & Logistics Centres) to continuously monitor these parameters.

Here’s how the system works:

- Sensors track real-time data on humidity, temperature, and nutrient flow.

- Alerts are triggered automatically if readings deviate from the optimal range.

- Irrigation systems adjust automatically based on root-zone moisture levels.

- Data dashboards help supervisors forecast growth timelines and yields.

By digitising what was once intuition, we turned fodder production into a measurable, repeatable process.

AI and Image Recognition: Bringing Consistency to Inputs

One of the most overlooked aspects of hydroponics is input variability. Even the best system fails if the grains used for sprouting differ in size, quality, or moisture content.

To solve this, Shunya developed an AI-based image recognition system that scans grain batches before use. The model identifies subtle variations in kernel size, colour, and texture — ensuring only grains that meet our scientifically defined parameters go into production.

This removes human subjectivity from sourcing and ensures that every batch starts with the same baseline.

Combined with the data from our IoT system, it allows for end-to-end traceability and quality control — from seed to feed.

The Shunya Stack: Where Science, Structure, and Software Meet

Our learnings have led to what we call the Shunya Stack — the integrated foundation of our approach.

It’s a phygital system — physical production powered by digital intelligence — made up of three pillars:

- Science Stack: Nutritional science guides the right mix of grains, water, and nutrients. Our protocols optimise sprouting for energy, digestibility, and palatability.

- Production Stack: Engineered systems like Viksit ensure climate adaptability and efficient water use.

- Technology Stack: Sensors, AI, and predictive analytics provide precision, consistency, and control.

Together, these stacks make hydroponic fodder not just innovative but operationally reliable — a key barrier that most earlier systems failed to overcome.

Predictability = Trust

For farmers, predictability translates into trust.

When milk yields rise and fodder arrives fresh every day, trust is built — not through advertising, but through outcomes.

In just nine months of commercial operations, Shunya’s four GLCs have:

- Produced multiple tons per day of fresh sprouted fodder that reaches animals within 3 hours after removal from trays.

- Served 2,500+ farmers across Uttar Pradesh and Haryana.

- Delivered measurable impact: up to 33% increase in farmer income in early markets.

That reliability isn’t luck — it’s technology applied with empathy and rigour.

Designed for India, Scalable for the World

Most hydroponic systems globally are designed for high-value horticulture in controlled greenhouses. Shunya’s challenge (and opportunity) was different: to make the technology work outdoors, affordably, and at scale for everyday rural use.

We’ve achieved this by combining:

- Low-cost materials and modular design, suited to rural energy and water conditions.

- Localized SOPs, accessible in regional languages through the SMART VIDHI platform.

- Data-driven optimization, enabling predictive maintenance and yield forecasting.

These make Shunya’s model scalable across India’s varied climates, from the humid east to the arid west, and potentially replicable in other developing dairy economies.

The Future: Predictive Production and Platform Intelligence

We’re now evolving from monitoring to prediction and automation.

Using accumulated production data, Shunya’s algorithms are learning to:

- Forecast mold risk before it occurs, enabling preventive interventions.

- Predict yield and quality for each tray based on sensor data.

- Optimize water and nutrient cycles for maximum output with minimum input.

Imagine a network of hydroponic units across India, each one continuously learning from the others; creating a living, self-optimizing fodder production ecosystem. That’s the future we’re building toward.

Why This Matters

Technology in agriculture isn’t about replacing farmers – it’s about de-risking their livelihoods.

India’s dairy economy depends on smallholders who own fewer than five animals. For them, fodder scarcity is not just an inconvenience; it’s the single largest cause of income instability.

Predictable, locally produced, climate-resilient fodder means:

- Healthier animals

- Better yields

- Higher incomes

- Reduced emissions

- Sustainable rural growth

When technology makes agriculture more predictable, it makes it more human-centred; freeing farmers from uncertainty and letting them focus on growth.

In Conclusion

The story of hydroponic fodder in India is no longer about novelty — it’s about reliability.

By combining engineering, data science, and grassroots understanding, Shunya Agritech has turned hydroponic fodder from a lab experiment into a scalable rural enterprise model.

In the end, predictability is the new productivity — and when technology meets agriculture with purpose, it doesn’t just grow plants.

It grows prosperity!

About Shunya Agritech

Shunya Agritech is a leading Fodder-as-a-Service provider building the future of dairy through innovation in hydroponic fodder in India. We grow and deliver affordable hydroponic fodder for small farmers, ensuring a year-round green fodder supply in India—regardless of season or geography. Our proprietary Nutri Ankurit Feed (NAF), grown using vertical farming for fodder, reaches farmers daily through a robust green fodder delivery network. Shunya’s hydroponic fodder delivery in India helps solve deep-rooted issues of nutrition, cost, and availability. Through our digital veterinary services in rural India, we also provide remote veterinary consultations for livestock, connecting farmers to expert care at the tap of a button. With our expanding network of Growth and Logistics Centres (GLC) and franchise-ready models, Shunya empowers communities, enhances milk productivity, and drives sustainable growth—one farm at a time.

Follow Shunya Agritech on Linkedin, X, Facebook & Instagram for regular updates. Subscribe to our Youtube Channel.